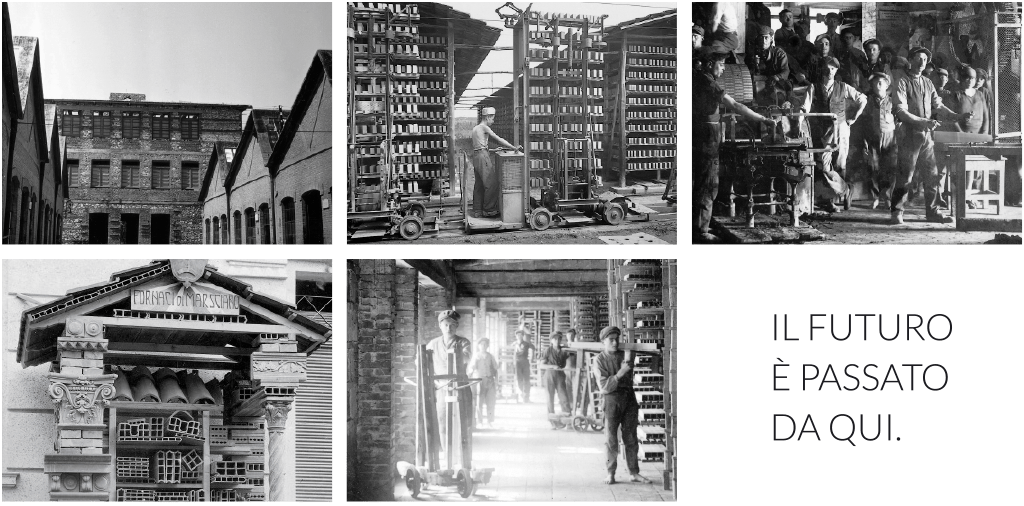

FBM, Fornaci Briziarelli Marsciano Spa, is a company with a history and tradition that goes back over a hundred years old and is today regarded as one of the most important in the building trade. Today, thanks to its forward views towards new techinques and methodologies, FBM is able to offer exclusive and innovative products to the market.

FUTURE IN PROGRESS

Four production sites, 250 employees, 80 national sale representatives and more than 12 distribution centres.

FBM is the leader in the production of bricks and all brick based products.

The Cements

Renders Red / Yellow / Testa di Moro - TER 1 ONE

TER1 is a pre-mixed dry mortar made of white portland cement, hydrated mortar, selected pure granulated brick and specific additives, added to aid a better workability of the paste, its adhesion to the base and finishing treatment. Ter 1 is also excellent when applied in the restauration of historical building.

Method of application

Remove all dust, oil stains, dirt and any uneven and excess material that could compromise bond in order to obtain a clean, even and solid supporting base. In the presence of old sementicious sub floor it is advisable to remove the degraded surface by mechanical means and then wash it with low pressure water to eliminate all dust, growths and any soluble salts. If the sub base needs to be strengthened apply a few coats of a water based acrilic primer prior to the application of TER1. Warning: the surface of application must be slightly dump but without any lose or puddled water as this could seriously impede its adhesion of the mortar.

Application

TER1 must be applied in thin layers of no more than 2mm by a metallic spatula by putting a light pressure on the supporting base to allow for the escape of any air trapped in the porous material. Before applying a new coat it is important to wait until the previous layer has started to adhere and that it has reached the consistency necessary to support the next one. The finishing coat of TER1can be applied before the product starts to set in circular motions with a sponge float while wetting the surface as needed. In the presence of high temperatures or high winds it is important to keep spraying water onto the surface to avoid a too quick evaporation of the water in the mix.

Colours available

- Red

- Yellow

- Testa di Moro

25KG Packs - PROFESSIONAL USE - KEEP AWAY FROM HUMIDITY

Renders - TER 1 Plus

Unversal finishing product with good covering capacity for the restauration and levelling of elevations even in historical buindings. To be applied in one single coat with a thickness of 3 to 30mm. Also for the restauration of any elevation and building facade where mesh reinforcement is used and for the levelling of regular and cosistent bases.

Base

The supporting base must be clean from dirt and dust. If organic the supporting base must be cleaned only by a thorough but simple water wash never with a high pressure jet washer. Once cleaned the base needs to be left to dry for an adequate amount of time (approx 10 days in favourable dry weather conditions). Preparation. For manual application add 7.5lt of water to a pack and mix with a manual mixer for 3 min. Apply a layer of the desired thickness with a steel trough. The application can be done in one or two layers, each of a thickness between 3mm and 30mm max. If the application is done by mechanical means then spray the product with a plastering machine. If used as a finishing plaster with a mesh this must be applied close to the surface but still kept completely covered by the product. Always protect it for seven days, especially in frosty conditions, during the application and the hardening. Curing time before applying the external coating: min 10 days. Working time: 3 hours.

Warning

Do not apply in temp below +5 °C. Do not mix with any other materials. Follow the technical data sheet.

Storage

Keep in a dry place, ideally on wooden shelves. Use by: min. 12 months under reg 1907/2006/EG attachment XVII a 20°C, e 65 % U.R.

25KG Packs - PROFESSIONAL USE - KEEP AWAY FROM HUMIDITY

MORTAR - TER2 rm5

Tinted mortar for red tinted surfaces.

Use

Render composit made of plaster/cement, limestone sand and selected red ground brick for all types of wall rendering (external tiles, exposed bricks, sandstone, limestone, etc) subjected to normal levels of static stress. Not suitable for walls made of extremely light or insulating bricks.

Preparation

Add approx 4,0lt of clean water to a pack and mix for 2 min with a handheld mechanical mixer or in a cement mixer. Do not add any other materials or products. Working time: 2 hours. Extra additives can be added only if authorised by the manufacturer.

Warning

Do not apply in temp below +5 °C. Do not mix with any other materials. Follow the technical data sheet.

Storage

Keep in a dry place, ideally on wooden shelves. Use by: min. 12 months under reg 1907/2006/EG attachment XVII a 20°C, e 65 % U.R.

25KG Packs - PROFESSIONAL USE - KEEP AWAY FROM HUMIDITY

MORTAR - TER2 m5

Wall mortar.

Use

Mortar for all type of walls subjected to normal static stress M5.

Base

Not in very cold temperatures when the bricks are frozen. Highly absorbent bricks that are too dry must be wetted before application.

Preparation

Add 4.1lt of water to a pack and mix with a hand held or in a cement mixer for 2-3 min to obtain a smooth and lump free paste.

Warning

Do not mix with any other materials. Working time: one hour. Do not apply the product in temp below +5 °C or over +30°C.

Storage

Keep in a dry place, ideally on wooden shelves. Use by: min. 12 months under reg 1907/2006/EG attachment XVII a 20°C, e 65 % U.R.

25KG Packs - PROFESSIONAL USE - KEEP AWAY FROM HUMIDITY

MORTAR - TER2 Gm5

Tinted render for yellow based surfaces.

Use

Render composit made of plaster/cement, limestone sand and selected yellow ground brick for all types of wall rendering (external tiles, exposed bricks, sandstone, limestone, etc) subjected to normal levels of static stress. Not suitable for walls made of extremely light or insulating bricks.

Preparation

Add approx 4,0lt of clean water to a pack and mix for 2 min with a handheld mechanical mixer or in a cement mixer. Do not add any other materials or products. Working time: 2 hours. Extra additives can be added only if authorised by the manufaturer.

Warning

Do not apply in temp below +5 °C. Do not mix with any other materials. Follow the technical data sheet.

Storage

Keep in a dry place, ideally on wooden shelves. Use by: min. 12 months under reg 1907/2006/EG attachment XVII a 20°C, e 65 % U.R.

25KG Packs - PROFESSIONAL USE - KEEP AWAY FROM HUMIDITY

MORTAR - TER2 M15

Wall mortar.

Use

Pre-mixed powder made of cement and limestone sand. Mortar for all type of walls subjected to static stress of above M15.

Application

Manually: mix the content of a pack with approx 3.75lt of clean water with a mechanical hand held or cement mixer to obtain a smooth paste. Do not mix with any other materials or products. Working time: two hours. Special additives can be added only if authorised by the manufacturer. Do not apply the product in temp below +5 °C or over +30°C.

Warning

Follow the technical data sheet.

Storage

Keep in a dry place, ideally on wooden shelves. Use by: min. 12 months under reg 1907/2006/EG attachment XVII a 20°C, e 65 % U.R.

25KG Packs - PROFESSIONAL USE - KEEP AWAY FROM HUMIDITY

MORTAR - TER2 TM5

Tinted mortar for dark tinted surfaces.

Use

Render composit made of plaster/cement, limestone sand and selected dark brown ground brick for all types of wall rendering (external tiles, exposed bricks, sandstone, limestone, etc) subjected to normal levels of static stress. Not suitable for walls made of extremely light or insulating bricks.

Preparation

Add approx 4,0lt of clean water to a pack and mix for 2 min with a handheld mechanical mixer or in a cement mixer. Do not add any other materials or products. Working time: 2 hours. Extra additives can be added only if authorised by the manufacturer.

Warning

Do not apply in temp below +5 °C. Do not mix with any other materials. Follow the technical data sheet.

Storage

Keep in a dry place, ideally on wooden shelves. Use by: min. 12 months under reg 1907/2006/EG attachment XVII a 20°C, e 65 % U.R.

25KG Packs - PROFESSIONAL USE - KEEP AWAY FROM HUMIDITY

ADHESIVE - TER 3 S1 Flex

Tile Adhesive C2 - TE - S1.

Product Description

Cementitious flexible grey adhesive, frost and water resistant under EN 12004:2007 (C2 TE S1) for ceramics and gres tiles for walls and flooring, patios, balconies and flooring with under floor heating. For internal and external use.

Base Preparation

The supporting base must be dry, levelled, free of frost, dust, solvent residues and any dirt. Curing times: when plastering according to EN 998-1 CS II-IV the drying time must follow the current guidelines; for chalk based plaster surfaces under EN 13279-1 max. 1 %, for plaster screeds 3,0 %; for calcium sulfate self-levelling screeds 0.5 %. These residual humidity values follow the CM and Darr methodology. Balconies, terraces and patios must have a min gradient of 2%

Prepartion and Application

Add appr 7,0 lt of clean water to the content of a pack and mix to obtain a smooth and lump free paste. Leave to rest for approx 5 min and then mix again. Working time approx 30 min depending on the type and condition of the support and of the site. If set withough gaps it is advisable to proceed by oating-buttering. At 20 °C and 65 % U.R. Walkable after 24h / possible seal after approx 24 h / ready in 7 days in private buildings / 28 days for commercial and general use.

Warning

Do not apply in temp below +5 °C. Do not mix with any other materials. Follow the technical data sheet.

Storage

Keep in a dry place, ideally on wooden shelves. Use by: min. 12 months under reg 1907/2006/EG attachment XVII a 20°C, e 65 % U.R.

25KG Packs - PROFESSIONAL USE - KEEP AWAY FROM HUMIDITY

ADHESIVE Bianco/Grigio - TER 3 C2TE

A ptl 52,5r cementitious based adhesive with high yield, with no vertical slip and long curing time for porcelain and ceramic ties.

Base Preparation

The supporting base must be levelled, clean, clear from debris and sufficiently dry. Chalk based and anidrite screeds must be totaly dry and treated with a water based acrilic primer.

Prepartion

Mix 25 kg of TER3 C2TE with 6,2-7,0 lt of clean water to get a smooth and lump free mix; leave it to rest for 5 min. Mix and then leave it to rest for 10 minutes and mix again. Working time: 4 hours. Add appr 7,0 lt of clean water to the content of a pack and mix to obtain a smooth and lump free paste. Leave to rest for approx 5 min and then mix again. Working time approx 30 min depending on the type and condition of the support and of the site. If set withough gaps it is advisable to proceed by oating-buttering. Walkable after 24h*/ possible seal after approx 24 h* / ready in 7 days in private buildings / 28 days for commercial and general use.

*at 20 °C and 65 % U.R.

Seal

After 4/6h for walls and 24h for flooring. Walkability: after 24h approx.

Coverage

3,5 - 8,0 kg/m2.

Application temperature

from +5°C to +35°C.

Storage

Keep in a dry place, ideally on wooden shelves. Use by: min. 12 months under reg 1907/2006/EG attachment XVII a 20°C, e 65 % U.R.

- White

- Grey

25KG Packs - PROFESSIONAL USE - KEEP AWAY FROM HUMIDITY

ADHESIVE Bianco/Grigio - TER 3 C2E S1

Flexible high performance mix binder adhesive with a cementitios base ptl 52.5 and with extended set time for thickness of 15 mm. For setting all types of tiles and mosaics, even on heated or multilayered screeds. For internal and external use.

Base Preparation

The supporting base must be levelled, clean, clear from debris and sufficiently dry. Chalk based and anidrite screeds must be totaly dry and treated with a water based acrilic primer.

Mix Preparation

For regular consistency: add approx 7,0 lt of clean water to a 25 kg pack. For a wet consistency add approx 8,0 lt of clean water to a 25 kg pack. Mix and then leave it to rest for 10 minutes and the mix again. Working time: 4 hours.

Application

Apply with a dented spatula directly on the supporting base. Choose a spatula that allows the back of the tiles to be made totally wet.

Seal

After 4/6h for walls and 24h for flooring. Walkability: after 24h approx. Coverage: 3,5 - 8,0 kg/m2.

Colours available

from +5°C a +35°C.

Storage

Keep in a dry place, ideally on wooden shelves. Use by: min. 12 months under reg 1907/2006/EG attachment XVII a 20°C, e 65 % U.R.

Colours available

- White

- Grey

25KG Packs - PROFESSIONAL USE - KEEP AWAY FROM HUMIDITY

Screed - TER 4 Base

Cementitious screed semi-rapid set CT - C20 - F4 - SE7

Use

Premixed cement and binder based screed with silica sand 0 - 4 mm that can be used as composit screed, as floating insulating screeds, as a underfloor heating screed. For non flat surfaces in humid and constantly wet areas, basements, garages and workshops as well as lofts, balconies and any remedial works.

Support base

The base must pass the minimum standard under the current normative.

Preparation and Application

Manually or by mixers. Regular machinery used for screed prep can be used. Add approx 1.9lt of clean water to a pack and mix continuously. The product must be applied when “ground wet” and working time is an hour from when the water was first added. No water when levelling. The area must be kept covered to avoid it drying too fast and special additives can be added only with the manufacturer permission.

Avvertenze

Rispettare la scheda tecnica del prodotto.

Storage

Keep in a dry place, ideally on wooden shelves. Use by: min. 12 months under reg 1907/2006/EG attachment XVII a 20°C, e 65 % U.R.

25KG Packs - PROFESSIONAL USE - KEEP AWAY FROM HUMIDITY

Screed - TER 4 Base Zero

Regular set cementitious screed CT - C20 - F4

Use

Premixed cement and binder based screed with silica sand 0 - 4 mm that can be used as composit screed, as floating insulating screeds, as a underfloor heating screed; for non flat surfaces in humid and constantly wet areas, basements, garages and workshops as well as lofts, balconies and remedial works.

Support base

The base must pass the minimum standard under the current normative.

Preparation and Application

Manually or by mixers. Regular machinery used for screed prep can be used. Add approx 1.9lt of clean water to a pack and mix continuously. The product must be applied when “ground wet” and working time is an hour from when the water was first added. No water when levelling. The area must be kept covered to avoid it drying too fast and special additives can be added only with the manufacturer permission.

Warning

Follow the technical data sheet.

Storage

Keep in a dry place, ideally on wooden shelves. Use by: min. 12 months under reg 1907/2006/EG attachment XVII a 20°C, e 65 % U.R.

25KG Packs - PROFESSIONAL USE - KEEP AWAY FROM HUMIDITY

Legante Cementizio - FBM66

Premixed cementitious adhesive to be used for the creation of floor surfaces with the addition of granulated brick.

Material

FBM 66 is an innovative premixed material which contains an hydraulic binder, selected fine aggregates, specific additives and fibrillated syntetic fibres. The addition of specific granulated brick mixes, once disactivated and thoroughly washed, will create a “cocciopesto” terracotta effect, giving to the flooring a warm and natural feel and colour. To one 25kg pack of FBM 66 (25 kg) add a 25kg pack of FBM ground brick (available in red, yellow and testa di moro).

Use

FBM 66 can be used for the creation of private and public floor surfaces such as sidawalks, paths, access ways and pavements.

Storage

FBM 66 must be stored in a dry and covered place in its sealed original package and in a temp between tra +5°C e +40°C. Once opened use all product or discard any remaining.

Application

For the preparation of FBM 66 it is advisable to use a mechanical mixer. Add 90% of the water needed in the mixer and only once the mixer is in motion add the brick granulate and mix it for 4/5 min to allow for its total hydration. Add then FBM 66 (see info on pack) continuously to avoid lumps. Mix for 3 to 4 min. If needed add the remaining water to reach the desired consistency and mix for a further 3-4 min. It is advisable to apply the product in temp between +5°C e +40°C as lower temperatures (<5°C) slow the setting quite drastically whilst high temp (>40°C) damage the workability of the paste. Once the floor surface is completed it is necessary to level it and to deactivate it by applying specific retardants/primers on its surface.

Coverage

10 kg FBM 66 + 10 kg Granulated Brick/m1 1cm.

Colour available (binder)

- White

- Grey

Colour available (granulated brick)

- Red

- Yellow

- Testa di moro Moor\'s head

25KG Packs - PROFESSIONAL USE - KEEP AWAY FROM HUMIDITY